Plastics are polymer compounds derived from the polymerization of small molecular organic compounds such as ethylene, styrene, etc., and can be classified broadly into thermoplastic and thermosetting plastics. Since the initial invention of plastics, various kinds of plastic products have become excellent substitutes for traditional materials such as paper, wood, metal, and ceramics in various manufacturing industries because of their advantages of a lightweight, high strength, good insulation, high transparency, excellent corrosion resistance, low cost and ease of fabrication. The current global production is estimated at about 300 million tons and it is expected to reach 500 million tons by 2050, most of which will be single-use products.

The various advantages of plastics have led to expansive growth in their production and consumption and this has also resulted in serious problems such as environmental pollution and waste disposal. Plastic debris is the major pollutant listed by the EU (61%) and the USEPA (78%). However, despite much effort in developing countries, less than 10% of the generated plastic wastes are being recycled to the original materials. As a result, about 75% of the wastes floating in the marine environment are plastics, and over two-thirds of them are not biodegradable.

A study by JR Jambeck reported that over 5 million tons of plastic wastes were discarded into the oceans in 2010. The plastic debris in aquatic habitats has caused immeasurable potential harm to marine ecosystems and also to the health of terrestrial organisms. Because of the mounting problems due to plastic pollution, governments in many countries have tightened restrictions on plastic products, in particular single-use ones. China is an active participant and promoter of plastic wastes control. In April 2017, the Chinese government approved a ban on imported “recyclable” solid wastes. The ban list included 24 kinds of solid wastes, among which non-industrial plastic wastes are the most prominent. The Chinese ban became effective at the beginning of 2018 and has had a far-reaching effect on global plastic production and on solid waste management. This study examines the global response to China’s ban on plastic waste imports, the current situation on plastic waste generation and disposition in China, and future prospects for sustainable resource recovery from non-recyclable plastic wastes.

The current global production of plastics is over 300 million tons, 20% of which is produced in China. It has been estimated that about 90% of discarded plastics are not recycled. China was the world’s leading importer of waste plastics, while since January 1, 2018, China’s import ban on waste plastics has been put into force, which has had a far-reaching effect on global plastic production and solid waste management. Southeast Asian countries like Malaysia have replaced China as the leading importer of plastic wastes. As the main exporter of waste plastics, the EU has released strategies and initiatives about plastics to restrict the use of microplastics and single-use plastics. Meanwhile, main European counties like the UK, Germany, and France have also taken their own active measures to realize the control of packaging waste and non-recycled plastic and the recycling of plastic wastes in several years. As For the US, some areas such as Seattle and San Francisco have positively responded to the global trend of plastic ban. However, the controversy over “plastic restriction” in the whole state obstructed the promulgation and implementation of the national plastic ban. On the whole, major companies and more than 60 countries all over the world have introduced levies or bans to combat single-use plastic wastes. The Chinese government began to rectify the domestic waste plastics market and the Ministry of Industry and Information Technology of China has clarified the threshold of waste plastic treatment capacity for key enterprises. In addition to landfills, direct recovery and waste to energy processes are the main disposal methods of waste plastics. Thermoplastics like PE, PP, and PET that are sorted out from the waste stream by citizens can be directly recycled to the primary material. The mixed waste plastics can be used as fuel in waste to energy plants, or as feedstock to pyrolysis plants that transform them to high value-added oil or chemical materials, which are more promising disposal methods of waste plastics.

Plastic production in the whole world, Europe, and the US.

Plastics are versatile materials that could be widely used in the fields of industrial production and our daily lives. The current production of plastics consumes 6% of the global oil production and, if the current trend continues, it will increase to 20% by 2050. As shown in Fig. 1a, the annual production of plastics in the world reached 335 million tons by 2016, with an annual growth rate of about 4%. China is the largest producer of plastic products, accounting for about 29% of worldwide production, followed by the North American Free Trade Area (NAFTA) (19%) and Europe (18%). Asia accounts for nearly half of the world’s plastic production.

Types and use of plastics

Take Europe for example. The dominant plastic products are polypropylene (PP), low-density polyethylene (LDPE) and high-density polyethylene (HDPE); these three compounds amount to 49.1% of all plastics in Europe.

1. Polypropylene (PP)

Polypropylene is a semi-crystalline thermoplastic plastic. It is widely used because of its high impact resistance, strong mechanical properties, and resistance to a variety of organic solvents, acids, and alkalis. The main applications of PP include the production of long and short polypropylene fibers, woven bags, packaging bags, injection-molded products which are used for electrical, telecommunications, lighting, lighting equipment, and TV sets of fame retardant parts. PP contributes about 24% in the plastic wastes category which is the largest amount of plastics found in MSW [12]. The high demand of PP in daily life causes the amount of PP wastes to increase each year.

2. Low-density polyethylene (LDPE)

Low-density polyethylene (LDPE), also known as high-pressure polyethylene, is suitable for various molding processes. Unlike HDPE, LDPE has more branching that results in a weaker intermolecular force, lower tensile strength, and lower hardness. The main LDPE products include thin-film products, such as agricultural film, ground cover film, agricultural membrane, vegetable shed film, packaging films such as candy, vegetables, frozen food, and another packaging, liquid packaging with blow molding film (milk, soy sauce, juice, soy milk); Heavy packaging bags, shrinkage packaging films, elastic films, lined films; building films, general industrial packaging films, and food bags, etc.

3. High-density polyethylene (HDPE)

High-density polyethylene (HDPE), also known as low-pressure polyethylene, is a translucent film with high crystallinity and a certain degree of non-polarity. It is an opaque white material with a specific density lower than water (0.941– 0.960). It is soft but slightly harder than LDPE and slightly stretchable. Due to its high-strength properties, HDPE is widely used in manufacturing milk bottles, detergent bottles, oil containers, toys, and more [13]. In addition, HDPE is also used to produce packaging film, ropes, woven mesh, fishing nets, water pipes, injection molding of lower grade daily necessities and housings, non-bearing load components, rubber boxes, turnover boxes, extrusion blow molding containers, hollow products, etc.

4. Polyvinyl chloride (PVC)

PVC is formed by the polymerization of the monomer (H2C=CHCl) and, therefore, consists of about 56% chlorine and 44% carbon plus hydrogen. Some minor compounds, such as plasticizers and anti-aging agents are added in the manufacturing process to enhance the heat resistance, toughness, and ductility of PVC; they may be potentially toxic so PVC is generally not used to store food and medicine. The compatibility of PVC with other additives makes it a versatile plastic. Regular PVC products include wire and cable insulation, window frames, boots, food foil, medical devices, blood bags, automotive interiors, packaging, credit cards, synthetic leather, etc.

5. Polyurethane (PUR)

Polyurethane is the most common plastic in the thermosetting family of plastics which accounts for only a small fraction of the plastic waste stream. Polyurethane (PUR) is a polymer with a repeating structural unit of the carbamate chain made from isocyanates and polyols. The density of PUR soft foam ranges from 0.015 to 0.15 g/cm. PUR products are divided into foaming products and non-foaming products. The foaming products include soft, hard, semi-rigid PUR foam, while non-foaming products include coatings, adhesives, synthetic leather, elastomers, and elastic fibers. Foam is the most widely used PUR product.

6. Polyethylene terephthalate (PET)

Polyethylene terephthalate is formed by the polymerization of the monomer (C10H8O4)n and, therefore, it consists of about 33% oxygen with the balance of carbon and hydrogen. PET plastics have good transparency, excellent dimensional stability, and electrical insulation. Containers made of PET have high strength, good transparency, are non-toxic, and are easy to fabricate; other applications of PET include electrical insulation, printing sheets, magnetic tapes, X-ray, and other photographic films.

7. Polystyrene (PS)

Polystyrene is made by polymerization of the monomer (C8H8)n. Like other plastics, they can be colored by means of additives. It is heat resilient and it offers strength and very low density which make this polymer suitable for use in many applications, such as food packaging, electronics, construction, medical, appliances, and toys. The wide range of applications results in a large volume fraction of PS in the MSW stream.

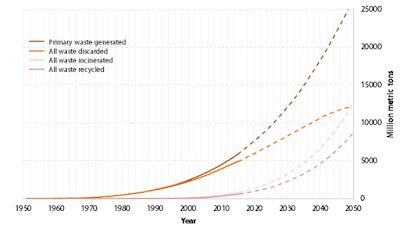

Cumulative plastic waste generation and disposal (1950–2015) and projection of historical trends to 2050.

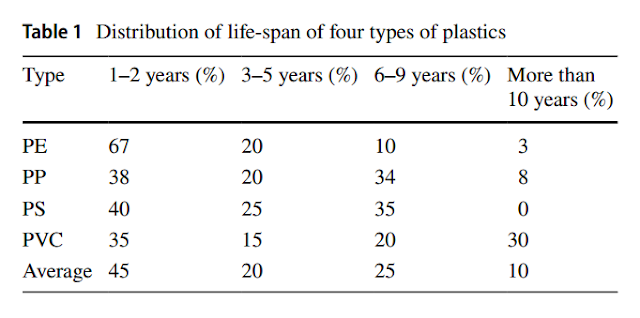

Table 1 Distribution of life-span of four types of plastics

The geography of plastic bag bans in the US (2018).

Resource recovery from plastic wastes

Thermoplastics like PE, PP, and PET that are sorted out from the waste stream by citizens can be recycled to the primary material. Waste PE, PP, and PET can be made into finished products after granulation, or be directly processed by simply cleaning, crushing, and plasticizing. The utilization mode without any modification is called direct recycling. Direct recycling is characterized by low operating costs, low equipment, and technological requirements. However, direct recycling also has a negligible deficiency. It cannot be used in the production of higher-quality products. In order to improve the quality of recycled materials, it is often necessary to add a certain proportion of virgin PE, PP, or PET materials, which accordingly increases the manufacturing cost. Modified regeneration refers to the modification of recycled materials by mechanical blending or chemical grafting, which could improve the mechanical properties of the modified regenerated products. Modified regeneration process routes are more complex and some also need specific mechanical equipment.

Combustion with energy recovery (waste to energy or WTE)

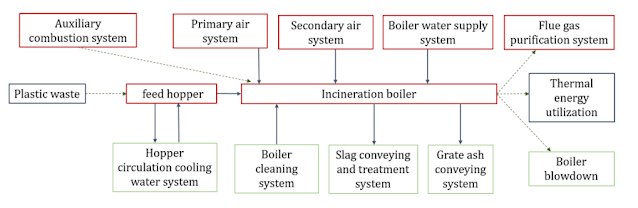

Mixed plastic wastes have a calorific value of about 35 MJ/kg which is about 85% of that of fuel oil. Therefore, they can be used to fuel power plants, in place of coal or oil. Combustion is fully controlled, does not require pretreatment of the mixed waste plastics and is a mature technology practiced in over one thousand plants worldwide, and is relatively mature. The flowsheet of a waste to energy process is shown in Fig below.

Process flow chart of combustion with energy recovery

The incineration of waste plastics is accompanied by the production of toxic organic gases such as polycyclic aromatic hydrocarbons, dioxins, and furans. Plastic components containing chlorine, nitrogen, and other additives will also release inorganic pollutants such as NOx and HCl during the incineration process, causing secondary pollution.

A report from environmental campaigners has claimed that UK incinerators will cause nearly £25bn of environmental harm during the next 30 years by burning plastics. Swindon Borough Council has proposed temporarily stopping the recycling of mixed plastics and instead of sending it to Energy-from-Waste. Swindon said this was because of uncertainty about exports and other markets.

Pyrolysis of plastic wastes to oil

Since petroleum is the principal source of plastics manufacturing, there is great potential for transforming plastic wastes into oil through the pyrolysis process. The oil produced by pyrolysis has a high calorific value comparable to commercial fuels. Different types of plastics can be defined based on moisture, fixed carbon, volatile matter, and ash content (proximate analysis). High volatile content favors the production of liquid oils, while high ash content reduces the number of liquid oils produced, thereby increasing gaseous yield and coke formation. Most waste plastics have very high volatiles and low ash content. It should be noted that the yield and quality of the pyrolysis products depend on the operating parameters of the pyrolysis process. The main parameters include temperature, reactor type, residence time, pressure, catalyst dosage, and the type of fluidizing gas and its flow rate. Figure 9 is a process flow chart of pyrolysis and gasification of township domestic waste.

Gasification

The Gasification of waste plastics produces a stream of gases including H2, CO, CO2, CH4, and N2. A significant advantage of gasification compared to pyrolysis is that it is more flexible. Gasification of waste plastics is mainly for the production of energy-carrying gas (H2) and synthesis gas (fuel, dimethyl ether, methanol, etc.), wherein the synthesis gas has an average calorific value of about 6–8 MJ/m3. The composition and application of the gas produced by the gasification process depend on the gasifying agent used. The main problem of plastic gasification is the high tar content in gas products, which is usually higher than the tar content in biomass gasification. Therefore, the gasification of waste plastics requires a very efficient gas cleaning system.

Gasification is expected to maximize the conversion of plastics into gas products or syngas. Tar and carbon are the main undesirable by-products. The gasification process includes complex chemical reactions: gas-phase drying, pyrolysis, reforming, and heterogeneous carbon gasification, which is summarized in Fig. below.

Direct recycling has advantages of low operating cost, less equipment, and processing requirements, but it can not be used to produce high-quality regenerated products. Incineration can realize energy recovery and volume reduction of waste plastics effectively whereas it will bring severe secondary pollution and the quality of the product is relatively low. Gasification has high process flexibility and high product quality. However, tar in syngas has become a serious problem in the large-scale application of gasifcation technology. Pyrolysis is not as mature as incineration, but the mild reaction conditions, easily controlled reaction process, high value-added products, and less secondary pollution make it a promising technology.

Industrial fow chart of pyrolysis gasifcation treatment technology

Flow chart of plastics gasifcation

Conclusion

This review provides concise summary of the global response to China’s ban on plastic waste imports, the current situation on plastic waste generation and disposition in China, and sustainable resource recovery technologies from non-recyclable plastic wastes. China’s import ban on waste plastics has been put into force since January 1, 2018, which led to the changes of waste plastics policy and market waste plastics globally. Southeast Asian countries like Malaysia have become the leading importer of plastic wastes. EU and the US have positively responded to China’s ban, strategy, and initiative released about plastics to restrict the use of microplastics and single-use plastics. Meanwhile, main European counties like UK, Germany, and France have also taken their own active measures in response to the China’s ban on waste plastics. In addition to the ban on waste imports, the Chinese government has also made certain regulations on the domestic waste plastics market. The global recovery rate of waste plastics is only about 10%. Waste to energy technologies based on pyrolysis and other thermal disposal means is promising technology to realize the utilization of non-recycled plastic wastes. Through comparing a variety of waste plastic disposal technologies, pyrolysis is more promising method because of its mild reaction conditions, easily controlled reaction process, high value-added products and less secondary pollution.(Indrawan Vpp)